Heat-treated wood undergoes a controlled pyrolysis process, in which it is heated to high temperatures that chemically alter the cell walls, enhancing its durability.This type of treatment has been used for over 30 years, especially in northern European countries (Scandinavian countries) and the species most affected by this process are pine, fir and ash.Today, heat-treated wood is widely used throughout Italy, where several leading manufacturers produce specialised equipment for this process.THE THREE STAGES OF THERMAL TREATMENTThe first stage involves drying the wood at around 100° until it becomes nearly anhydrous (0% moisture content). The duration of the heat treatment varies depending on the timber species, thickness, and initial moisture content. During the drying phase, the moisture in the wood is released and evaporates.In the second phase, the timber is subjected to a temperature of around 180 to 220°C, triggering a chemical transformation. This second phase follows the drying stage directly, and typically lasts between 4 and 5 hours. To prevent combustion, either a vacuum is created or steam is introduced into the treatment chamber.In the third phase, the temperature is gradually lowered to ambient levels. Steam is added during this phase to bring the wood’s moisture content to an optimal 7–8%, in a process lasting between 5 and 10 hours.There are two types of heat treatment: “S” stands for Stability, and “D” for Durability.For products that only require dimensional stability, the temperature used is typically no greater than 190°C; for products needing increased durability, the temperature must reach approximately 215°C."S" class wood is usually intended for indoor use, while "D" class wood is suitable for both indoor and outdoor applications.

The heat treatment modifies both the chemical and physical properties of the wood. These transformations begin at around a temperature of 150°C and increase as the temperature rises. The process changes the structure and molecular composition of the wood, breaks down its hydroxyl groups, and alters the wood cell wall. As a result, the wood swells less and loses some of its original weight. It also increases its biological durability and darkens the natural colour of the wood. The final colour of the wood becomes more intense as the treatment temperature increases.

With the removal of resin during the heat treatment, the wood becomes lighter. The moisture content and pH level decrease, while thermal insulation properties are improved. Since heat-treated wood absorbs significantly less moisture, it remains more stable and enjoys a longer service life.

An additional benefit of heat treatment is that it alters the entire wood structure, unlike surface treatments, which only protect the outer layer and leave the interior untreated.

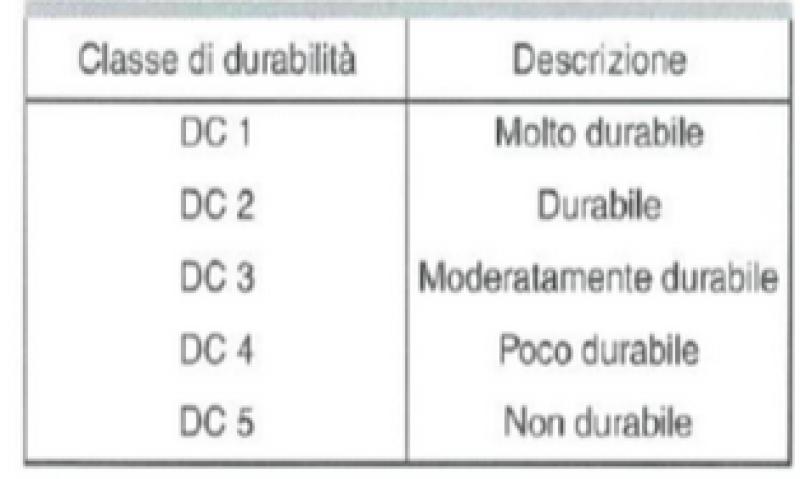

With heat treatment, softwood (pine and fir) can be used for applications requiring high durability. Once the drying process is complete, the wood can reach durability class 1–2, as defined by European standard EN 350-2.When exposed to ultraviolet rays, all outdoor wood eventually undergoes discolouration and will tend to grey.

This even occurs with impregnated or heat treated wood.

In order to preserve the original colour, it is recommended to apply a natural-based stain with pigments free from harmful chemicals, which may also comply with the Minimum Environmental Criteria (MEC).

12/01/2026 |

Read the full news20/11/2025 |

Read the full news