Since 1976, Holzhof has been looking to the future with determination, investing in advanced technologies and continuous staff training. An ongoing commitment to delivering quality products and services while ensuring a safe, state-of-the-art work environment.Holzhof products are manufactured entirely in-house, offering an excellent price-quality ratio and full customisation options to meet each customer’s unique requirements. By producing all components internally, we are able to guarantee long-lasting products with immediate spare parts availability at any time.In order to meet the market's demands quickly, we have dedicated a substantial area to storing standard products, significantly reducing lead times and enabling fast delivery of many items.Our commitment to quality extends beyond our products to the safety and well-being of individuals. Holzhof operates in full compliance with the current regulations, ensuring product safety in accordance with UNI EN 1176, and holding UNI ISO 45001 certification for the protection of the workers' health and safety and the work environment.

We have two professional planers, ideal for ensuring smooth, uniform and high-quality surfaces on every type of wood. This tool allows us to perform precise and custom work and guarantees flexibility and customization of products, because it enables us to obtain any type and size of profile.

We have four modern CNC woodworking centers dedicated to wood processing. Thanks to these high-tech systems, we can guarantee maximum precision, consistent quality and great production flexibility, creating both standard products and custom solutions, always with high standards of reliability and finishing.

For wood treatment, we use an autoclave system that allows us to guarantee high protection and greater durability over time. We exclusively purchase Nordic coniferous lumber, selected for its quality and resistance. The process takes place entirely within our facilities: the wood is first processed and then subjected to autoclave treatment, allowing the impregnating product to penetrate deeply. In this way, we significantly extend the useful life of the structures.

We have a modern wood heat treatment facility, designed to ensure maximum efficiency and quality in the stabilization and durability process of the material. Thanks to precise control of temperature, humidity and processing times, the facility allows wood to be treated at controlled temperatures up to 220°C, under vacuum conditions or with steam introduction, thus avoiding the risk of combustion. Thanks to this treatment, wood becomes more dimensionally stable, more resistant to atmospheric agents, fungi and insects, significantly extending its lifespan without the use of chemical additives.

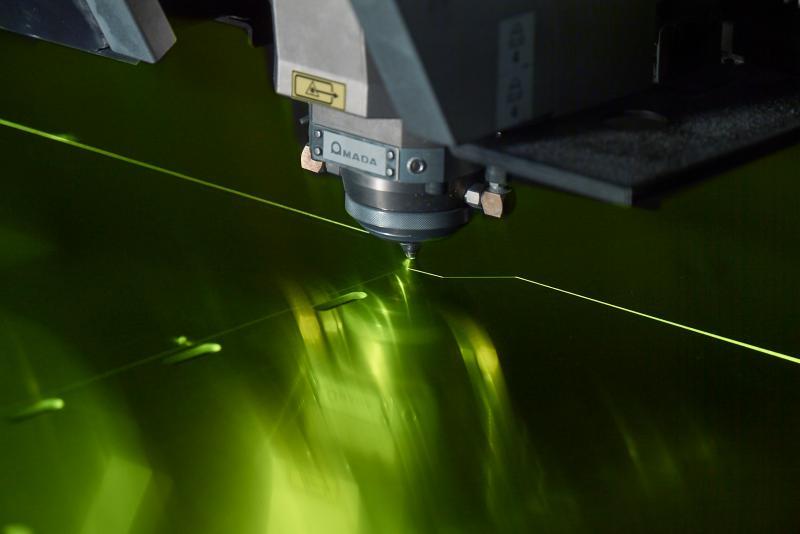

We use state-of-the-art machinery for sheet metal cutting, ensuring some of the highest levels of precision available on the market. This advanced technology allows us to achieve clean and perfect cuts, minimizing waste and optimizing material usage. Our new system, in addition to delivering top-level performance, is designed with particular attention to energy efficiency. Thanks to its reduced consumption, it significantly contributes to our commitment to environmental sustainability by reducing the ecological impact of production.

For the welding of standard products, we use two high-precision automatic robots that ensure uniformity, quality, and speed in production. For non-standard products, the work is entrusted to highly specialized and certified personnel, holding a welding license and proven experience in manual welding. In this way, we guarantee maximum reliability even in the most complex and customized operations. Moreover, we are UNI EN 1090 certified, ensuring the compliance of our welding and structural fabrication processes with the strictest European standards in terms of safety and quality.

We have four modern CNC machining centers dedicated to aluminum processing. Thanks to these high-tech systems, we can guarantee maximum precision, consistent quality and great production flexibility, creating both standard products and custom solutions, always with high standards of reliability and finish.

We have various machines for shaping metal components, such as tube benders, calenders, press brakes, etc. Thanks to a constantly updated machine fleet, we can guarantee precision, efficiency and versatility in every production phase, easily adapting to both standard and customized products.

We have three modern CNC machining centers dedicated to polyethylene processing. Thanks to these high-tech systems, we can guarantee maximum precision, consistent quality and great production flexibility, manufacturing both standard products and custom solutions, always with high standards of reliability and finishing.

Our rotational molding plant allows us to manufacture polyethylene components of any shape and size, ensuring maximum design and production flexibility. Thanks to in-house production, we can easily manage spare parts availability and significantly reduce delivery times, ensuring fast and efficient service to our customers. Furthermore, the production process has a lower environmental impact: we only handle raw powder material, avoiding road transport of large volumes of finished products, thus reducing logistics-related emissions.

12/01/2026 |

Read the full news20/11/2025 |

Read the full news